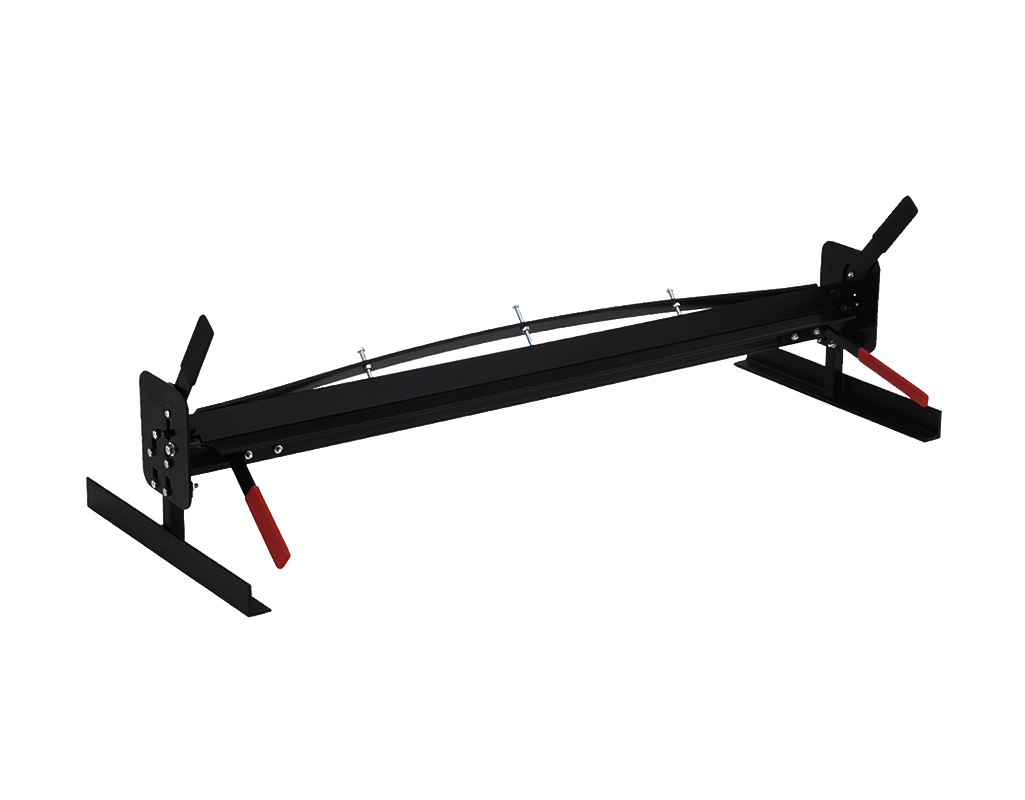

Portable mini Brake

Features

Portable design offers the capability to easily move brake from one setting to another.

Produces bends in sheet metal up to 135 degrees.

No fixed throat depth.

Strengthening ribs on the brake’s anvil and apron ensure consistent bends.

A safety-conscious, cam-over style clamping mechanism, similar to much larger shop-floor brakes, keeps the anvil secure in any position.

Optional legs available separately.

Details

Make big or small fabrications on the job with this lightweight and portable tool! The versatile Mini-Brake produces bends up to 135 degrees in sheet metals, including aluminum, copper, and 22-gauge galvanized steel. The brake’s compact size can accommodate sheet metal stock up to 4-feet wide, in any length, because there is no fixed throat depth to contend with.

Use the Mini Brake anywhere on the job site, even on a truck tailgate, for a variety of fabricating tasks from large HVAC transitions to narrow roof flashing to structures as small as a 4-inch square. Strengthening ribs on the brake’s anvil and apron ensure consistent bends. A safety-conscious, cam-over style clamping mechanism, similar to much larger shop-floor brakes, keeps the anvil secure in any position. Optional legs are available separately.